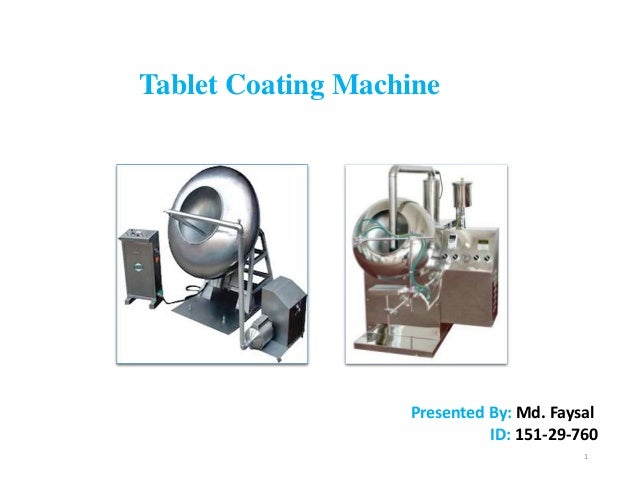

tablet coating equipment

Equipment efficiency coating efficiency is achieved by dividing the net increase in the weight by the total of the nonvolatile coating applied to the tablet. Treating coating tablet press tooling. The tablet coating have number of advantages like masking odor taste color of the drug providing physical and chemical protection to drug protecting drug from the gastric environment.

A tablet is a pharmaceutical oral dosage form oral solid dosage or osd or solid unit dosage form tablets may be defined as the solid unit dosage form of medicament or medicaments with suitable excipients it comprises a mixture of active substances and excipients usually in powder form pressed or compacted from a powder into a solid dose.

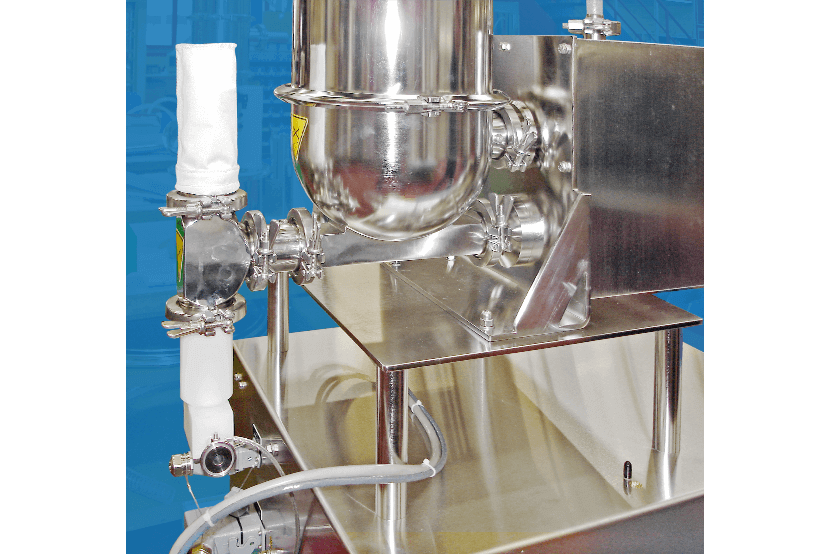

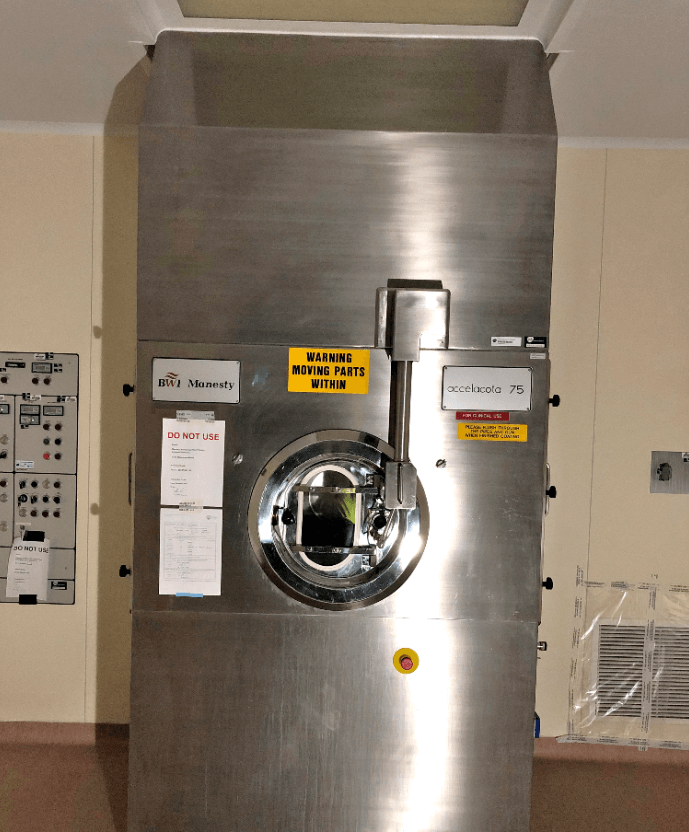

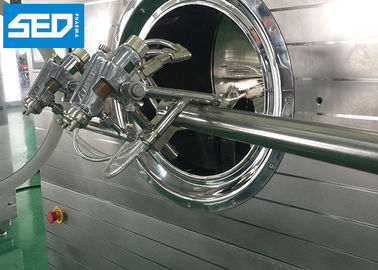

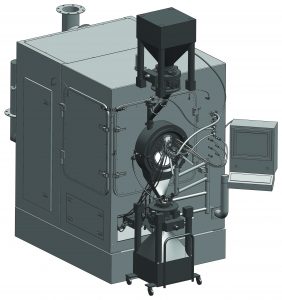

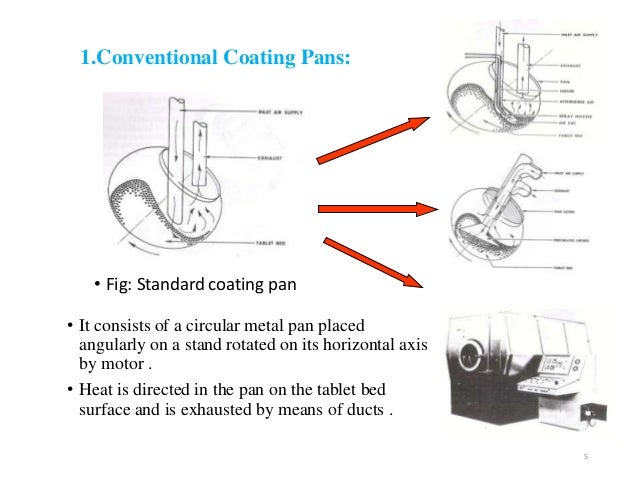

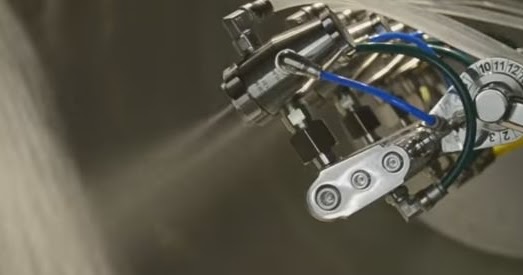

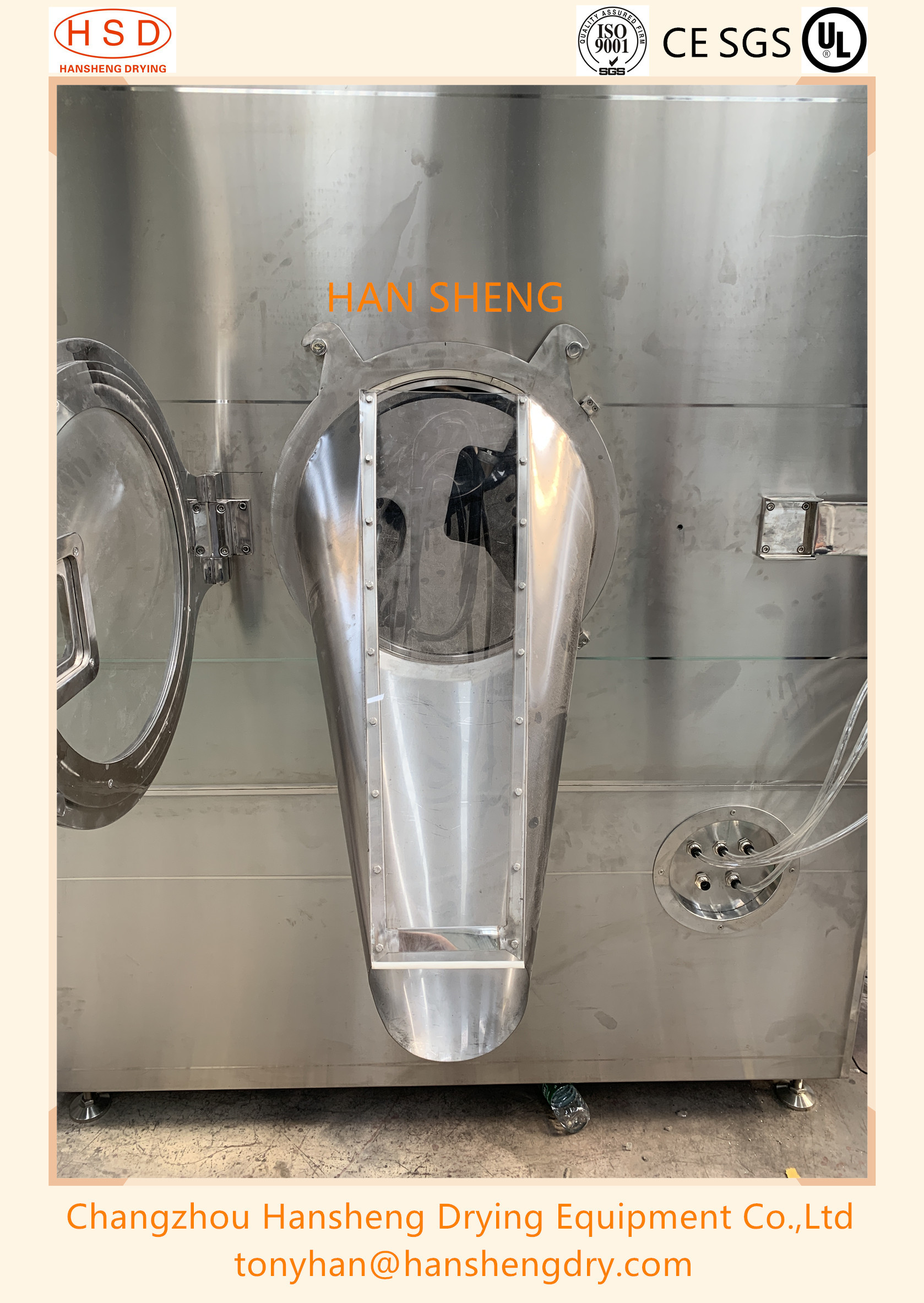

Tablet coating equipment. Objectives of tablet coating 4 5. Facility ancillary equipment d. Tablet coating is a common pharmaceutical technique of applying a thin polymer based film to a tablet or a granule. Tablet pressing tools are polished by automatic drag finishing machines to achieve mirror polishing.

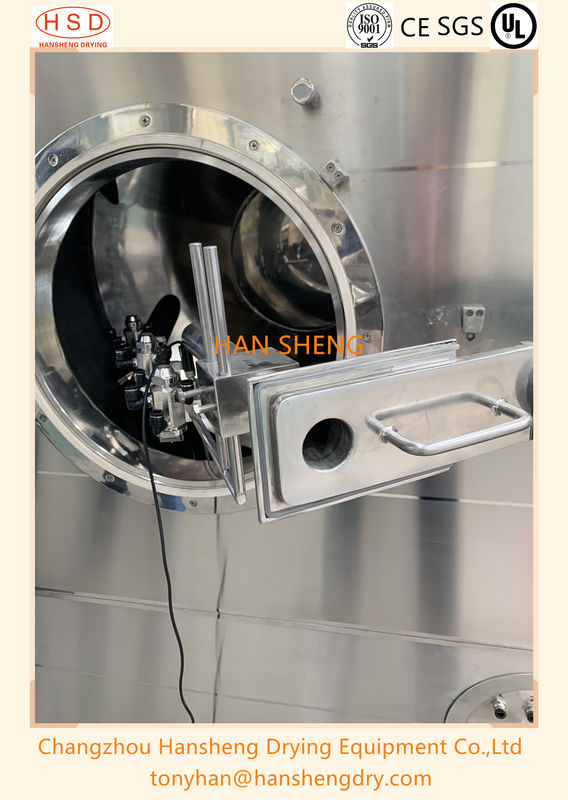

The continuous partial coating and recycling will eventually result in the tablet to be fully coated. Tablet film coating is a technology driven process and the evolution of coated dosage forms relies on advancements in coating technology equipment analytical techniques and coating materials. Components consideredin tablet coating tablet properties shape tolerance surface area coating process a. The ideal coating should be at 90 95.

Walls of t he coating equipment the tablets must be resistant. The kind of treatment will depend on the specific task at hand. An example of all of these types of coating is a product label on many drinks bottles one side has an all over functional coating the adhesive and the other side has one or more decorative coatings in an appropriate pattern the printing to form the words and. The coating itself may be an all over coating completely covering the substrate or it may only cover parts of the substrate.

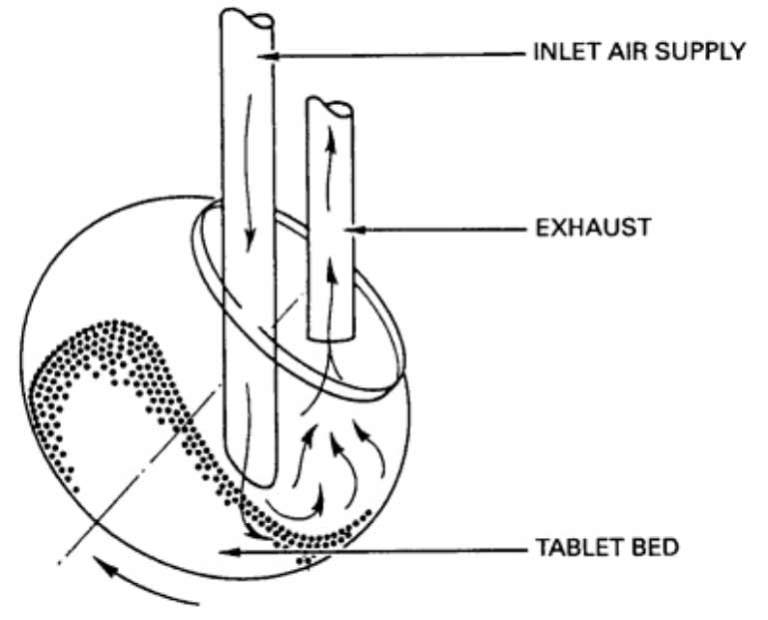

Automation of coating process coating composition which involves polymers color plasticizer solvent. A tablet coating machine is an equipment that coats the external surface of a tablet using a thin film of coating material. Working principle of tablet coating machine is relatively simple where the application of coating material is done on a moving bed of tablets and removing rapidly the solvent using a current of hot air. Tablet coating is the key step involved in the manufacturing of tablets having controlled release delayed release profiles.

3 primary components of tablet coating are tablet properties coating process and.