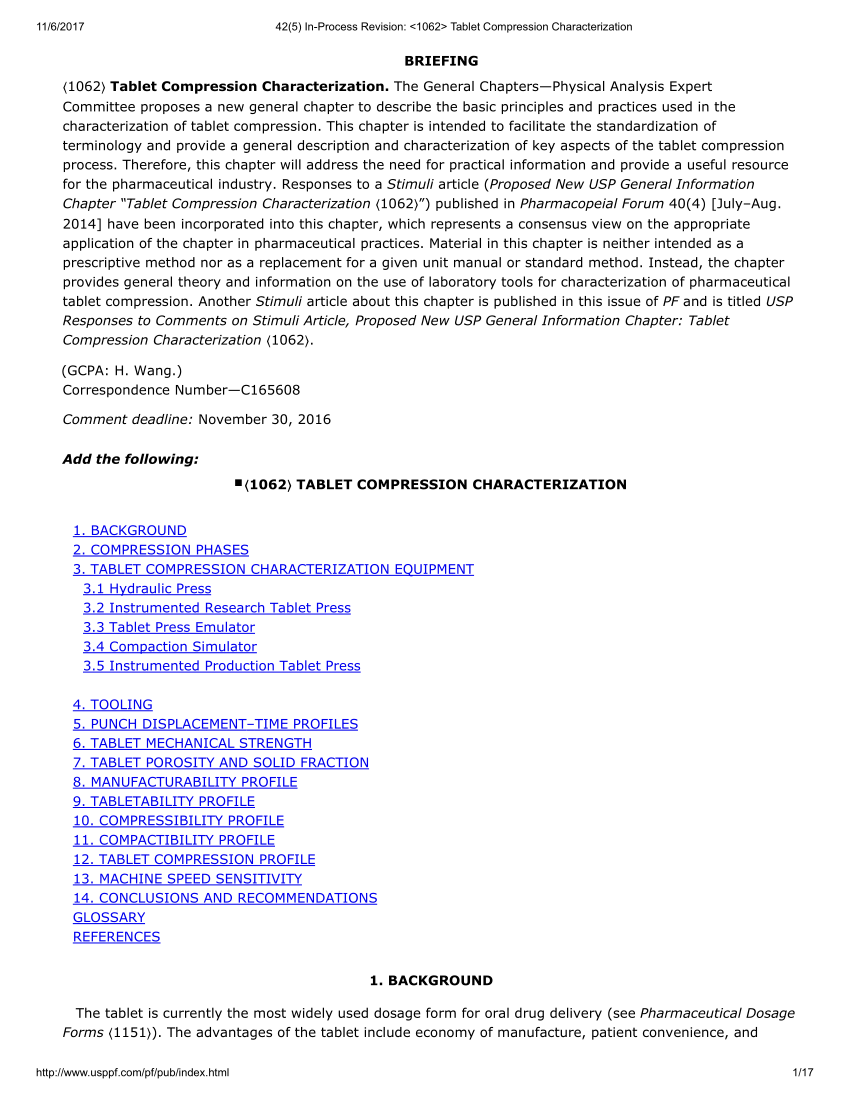

tablet compression pdf

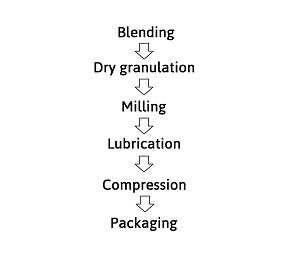

Granulation is the process of collecting particles together by creating bonds between them. Too low or too high moisture contents may influence the chemical and physical stability of the final tablet. Nomenclature labeling and data for evaluation.

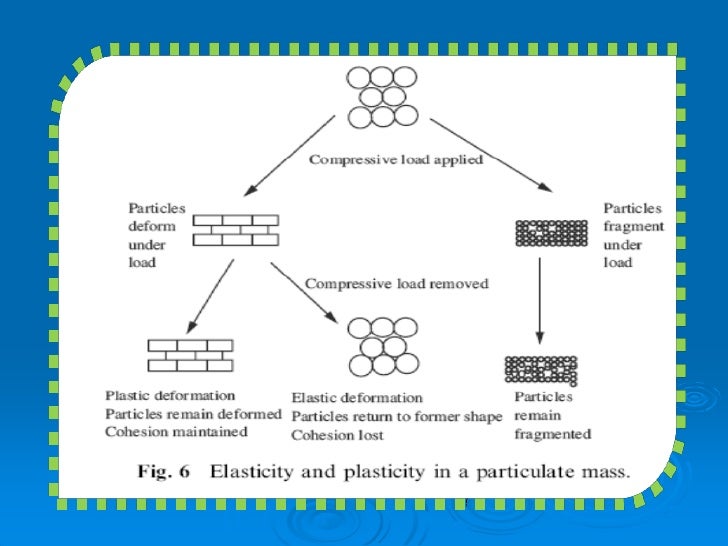

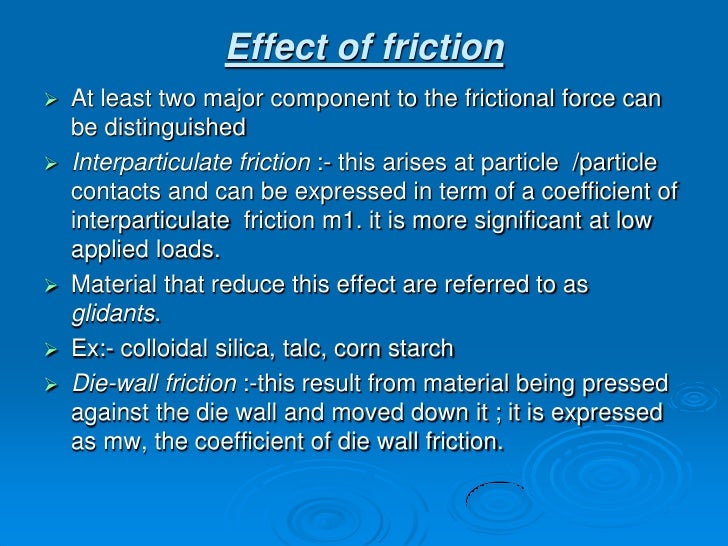

High degree of compression setting make s tablet to sep arate.

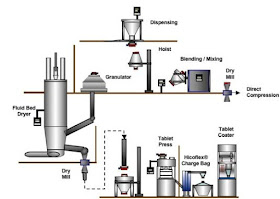

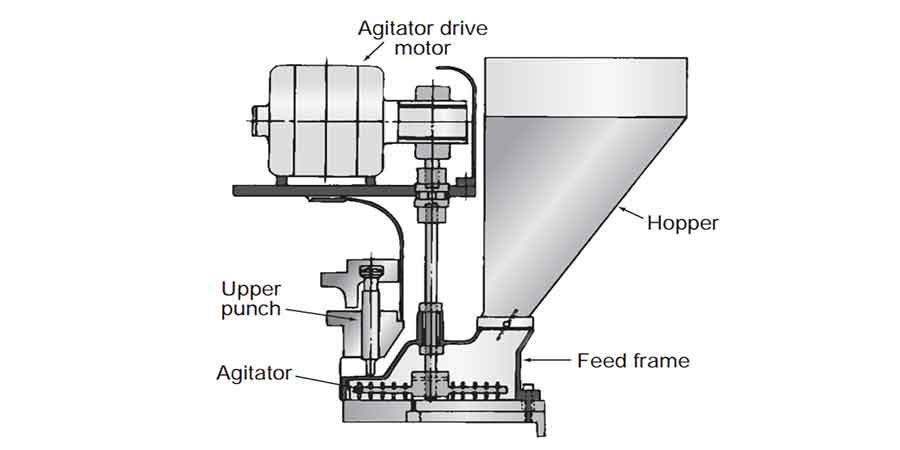

Tablet compression pdf. For a fact there are many tableting machines in the market with hundreds of parts and components. However for the scope of this article i will focus on the main parts that you ll find in any tablet compression machine. If one were to make tablets from granulated sugar versus powdered sugar for example powdered sugar would be difficult to compress into a tablet and granulated sugar. Article download pdf crossref view record in scopus google scholar.

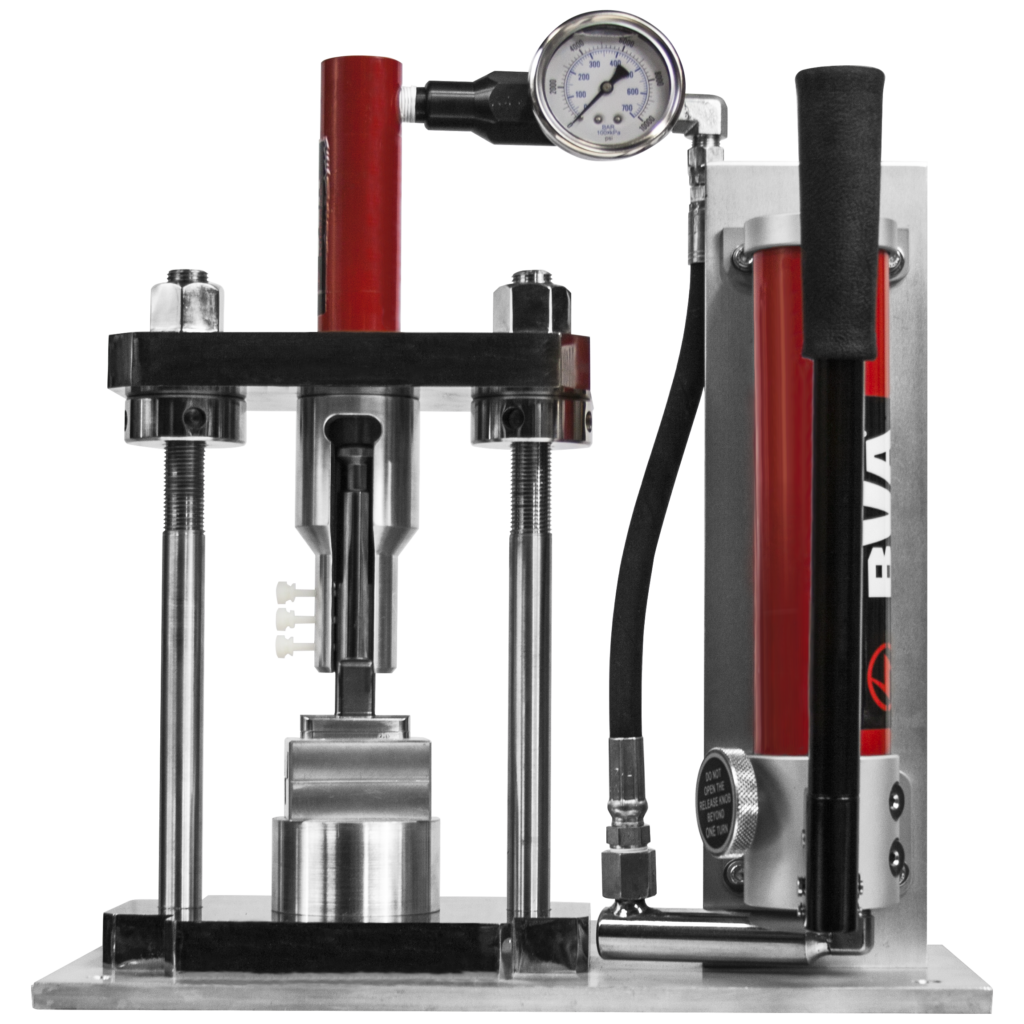

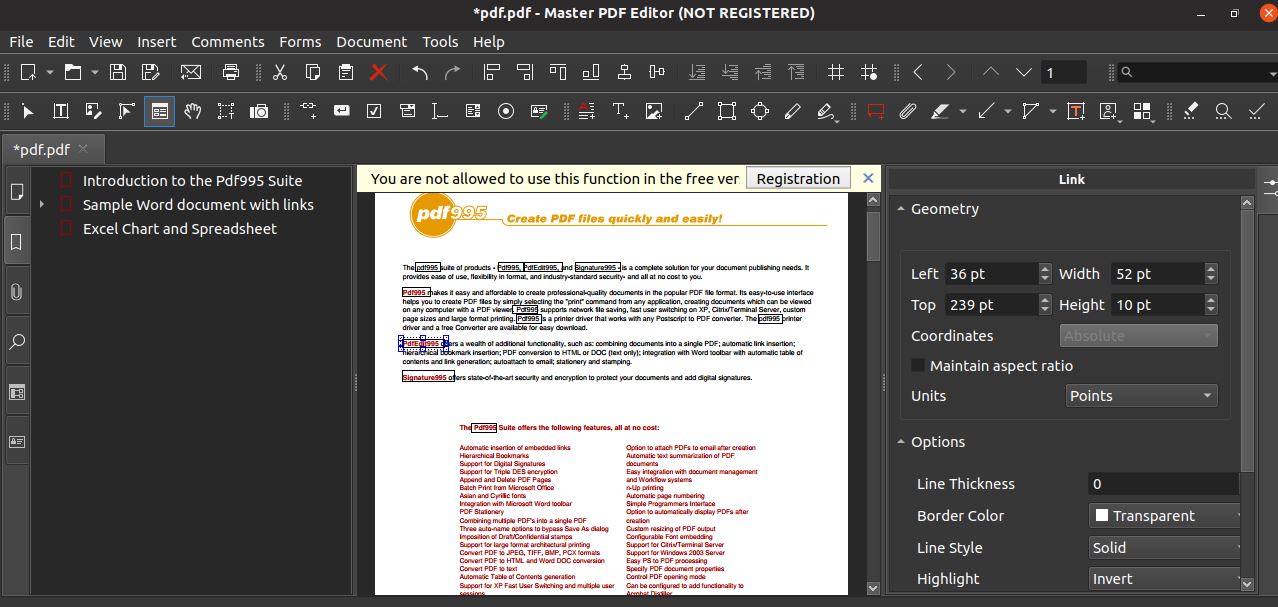

A tablet press is a mechanical device that compresses powder into tablets of uniform size and weight. Bonds are formed by compression or by using a binding agent. The compression is done either by a single punch machine stamping press or by a multi station machine rotary press. Pdf introduction the.

View record in scopus google scholar. Pdf tablet coating is a common pharmaceutical technique of applying a thin polymer based film to a tablet or a granule containing active. Compression coating hot melt coating powder. Tablet compression tablet press.

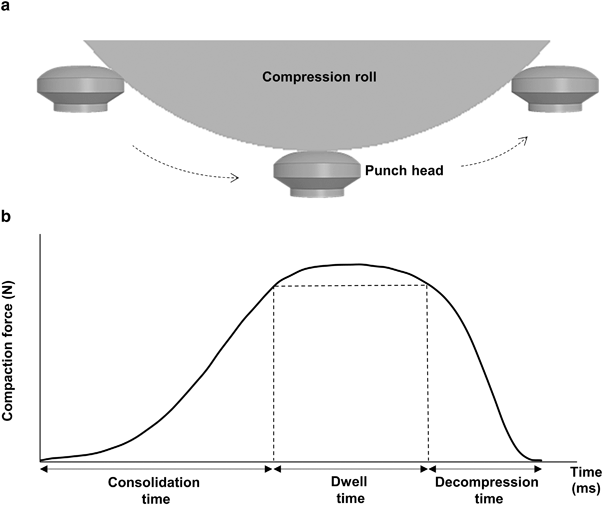

Knowing tablet compression machine parts is critical in the tablet making process. Powders for tablet making. When a wet granulation technique is employed control of the residual moisture after the drying step is important for smooth tablet compression. After the preparation of granules in wet granulation or sized slugs in dry granulation or mixing of ingredients in direct compression they are compressed to get the final product.

Generally wet granulation of the mix before compression reduces the risk for segregation. A tablet press can be used to manufacture tablets of a wide variety of materials including pharmaceuticals nutraceuticals cleaning products industrial pellets and cosmetics to form a tablet the granulated powder material must be metered into a cavity formed by two punches and a die and. High temperature adjustment. Food and drug administration.

Main s urface into individual surface. Hwang and peck 2001. Department of health and human services. A systemactic evaluation of the compression and tablet characteristics of various types of microcrystalline cellulose.

A void defective punches. Guidance for industry tablet scoring.